Technology Has an Address

Today’s recycling requires advanced technology to meet the demands of multiple material streams, hard to recover materials, and cost efficiencies. swissRTec offers a wide-range of equipment and processing systems to provide recycling solutions for e-scrap, mixed scrap metal, aluminum composites, white goods, car bodies and auto shredder residue (ASR), and, other composite materials.

Composites are objects comprised of more than one raw material. E-scrap, for example contains a wide ra nge of composites, including electrical and electronic equipment, wires, printed circuit boards, and mixed plastics. By breaking up and separating these composites, valuable high-yield raw materials such as copper, aluminum, steel, and plastics can be recovered.

nge of composites, including electrical and electronic equipment, wires, printed circuit boards, and mixed plastics. By breaking up and separating these composites, valuable high-yield raw materials such as copper, aluminum, steel, and plastics can be recovered.

swissRTec prides itself on engineering, manufacturing, and commissioning processing solutions that can be tailored to meet the needs of often difficult to handle material streams, such as ASR. Using swissRTec’s high quality shredding and delamination/separation plants, recycling facilities can maximize recovery and purity rates for materials.

swissRTec America, Inc., headquartered in Kensington, New Hampshire, is a wholly owned subsidiary of the Swiss-based swissRTec International. For decades, the company has been marketing its technology and mechanical systems to the international recycling industry. The company opened its US office in 2014 to better service the North American market.

swissRTec’s motto, “Technology Has an Address”, is particularly applicable in the growing field of composite material recycling. Auto shredder residue is one stream for which swissRTec has applied its expertise and technology to offer solutions that work. The 2015 European Union regulations require a recycling rate of 95% for scrapped cars. This is driving the recycling sector to look at innovative technologies to recover more materials, including the metals typically left behind in ASR. Though difficult to separate from the residue, the metals do offer potential high value due to their substantial copper content. And while such requirements do not exist in the U.S., ASR is a material stream of concern to the recycling industry.

Equipment with “Super Hero” Strength

According to Bernhard Mueggler, President and CEO of swissRTec America, “Demand for larger recycling systems is a growing trend in the marketplace. It’s a trend not likely to go away soon.”

The company’s Kubota Vertical Shredder can process large and small domestic appliances, metal scrap and other bulky items. With its powerful breakers and multiple layers of grinders, it breaks down and grinds up materials down to one inch or less in size in a single pass. This vertical shredder can be used as a stand-alone unit or in combination with other processing technology. With the incorporation of magnets, eddy current separators, screens, sensor sorters, and other techniques, bulky material is quickly separated into high quality ferrous, non-ferrous, plastic, and other materials.

metal scrap and other bulky items. With its powerful breakers and multiple layers of grinders, it breaks down and grinds up materials down to one inch or less in size in a single pass. This vertical shredder can be used as a stand-alone unit or in combination with other processing technology. With the incorporation of magnets, eddy current separators, screens, sensor sorters, and other techniques, bulky material is quickly separated into high quality ferrous, non-ferrous, plastic, and other materials.

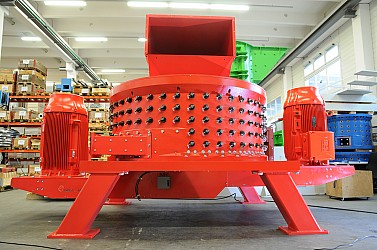

Its cutting edge delamination and separation plant allows for additional processing and purification of non-ferrous metal concentrate for even higher yields. swissRTec’s largest delamination mill to date—the CCM20RT—is the result of more than a decade of experience. With a 6.5-foot rotor diameter it weighs in at 21 tons and has a drive with up to 840 horsepower. Along with downstream separation systems, it provides complete milling and high quality separation and is constructed to withstand the rigors of ASR processing.

Its cutting edge delamination and separation plant allows for additional processing and purification of non-ferrous metal concentrate for even higher yields. swissRTec’s largest delamination mill to date—the CCM20RT—is the result of more than a decade of experience. With a 6.5-foot rotor diameter it weighs in at 21 tons and has a drive with up to 840 horsepower. Along with downstream separation systems, it provides complete milling and high quality separation and is constructed to withstand the rigors of ASR processing.

What’s the process behind its powerful delamination mills? The latest impact milling technology that forces thousands of collisions within the mills to break down pre-shredded composite materials which then “disintegrate” into individual components. These segregated materials are milled further into tiny, smooth balls for separation. Lower density material is separated from higher density material resulting in highly purified and valuable outputs, such as copper and aluminum.

technology that forces thousands of collisions within the mills to break down pre-shredded composite materials which then “disintegrate” into individual components. These segregated materials are milled further into tiny, smooth balls for separation. Lower density material is separated from higher density material resulting in highly purified and valuable outputs, such as copper and aluminum.

See swissRTec systems in action through videos posted on its website.

Recycling Commitment

swissRTec knows the importance of recovering valuable metal and other raw materials to use in the production of new goods and materials.

With its high-efficiency drive systems, the company reports that operators also benefit from the lower energy cost, seeing at least a 5 percent reduction, according to swissRTec.

And, as Mr. Mueggler states, “By keeping its core focus on shredding, delamination, separation, swissRTec is able to adapt to changing industry trends, meet customer demands, provide profitable material recovery, and continue its dedication to the recovery of high-yield and quality valuable raw materials.”

With its relatively new venture into the North American market, Mr. Mueggler says that “the international company felt that becoming a NERC Advisory Member would help us promote the swissRTec name and business throughout the United States. NERC members are leaders in materials management which is our core business.”